1. Slump Test

Slump Test aims to show the workability or kelecakan raw terms (how muddy / watery / Muddy) a concrete mortar.

See Part 2

2. Compression Test Press Test or Test

Press Test test aims to find out how much power can be achieved concrete. Test Press Test is of course done at the time the concrete has hardened.

The test must always be done with caution. Test less attention to proper procedures can give results that are not appropriate.

SAMPLINGThe first step is to take samples or samples from the batch of concrete, for example from concrete trucks or ready-mix truck. This sampling should be done as soon as possible so the truck had reached the project site. Thus, samples taken at the location, not at Batching Plant, ie places where the ready mix truck loading and mixing raw materials of concrete.

Samples can be taken in two ways:

1. For approval may be used or not, the sample taken after 0.2 cubic meters of concrete has been poured (cast) first. So, once the concrete is poured as much as 0.2 cubic meters, then the sample was taken. If okay, the concrete may be used. If not, of course refunded.

2. For routine checks: sample taken from each of the three sections of concrete in the truck load.

TEST slumpThe goal is to ensure that the concrete mixture is not too watery and not too hard. Slump is measured must be within range or within the limits of tolerance of the target.

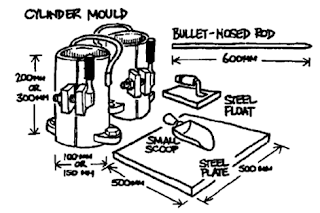

Equipment

Slump cone * standard (diamter of 100 mm, bottom diameter 200 mm, and height 300 mm)

* Small Sekup

* Iron rod cylinder (length 600 mm, diameter 16 mm)

* The ruler / ruler / Ruler

* Board slump (size 500 × 500 mm)

Procedure

* Clean the cone. Dampen the surface with water, and place it on the board slump. Slump board must be clean, stable (not easily moved), not dusty, and not tilted.

* Take concrete samples

Standing on the ground (ear) that existed at the cone. Fill cone with a third of the sample. Padatkan by rodding, ie concrete poking as much as 25 times. Do it from the outer to the middle

The contents of another until it reaches 2 / 3 parts cone. Perform rodding 25 times, but only up to the top of the first layer. Not to the bottom cone

Fill until full, do it again rodding 25 times up to the top of the second layer.

Flatten the top of the concrete was "flooded" by using an iron rod. Bersikan board slump in the vicinity of cone. Press and hold down cone, and release a foothold.

Lift the cone slowly. Do not let the samples move / shift

Turn the cone, place the next sample, and place an iron rod on top of the inverted cone.

Measure the slump some point, and record the average

* If the sample fails or is outside the tolerance, then another sample should be taken, then performed slump test. If it still fails too, then the concrete may be rejected.

Compressive strength

Compressive strength test aims to determine the compressive strength of concrete that had hardened. This test is conducted in the laboratory, and certainly not at the project site (off-site). What can be done at the location (site) just make or print a concrete cylinders to be tested. Kan, sampled at the site. Not allowed to bring samples to the laboratory, then put into cylindrical molds. Cylindrical molds must be provided at the project site.

Concrete strength can be measured in units of MPa or other units such as kg/cm2. This shows the compressive strength of concrete measured at 28 days concrete age.

Sample Preparation Equipment

* Tube / cylindrical molds (diameter 100mm x 200mm H, or a diameter of 150 mm x 300 mm H)

* Sekup small.

* Iron rod cylinder (diameter 16 mm, length 600 mm)

* Steel plates as a holder

Cylinder Sample Preparation Procedure

* Clean up mold inside surface of the cylinder and coat with oil form, so that concrete mortar does not stick on the surface of the metal from the mold.

* Take samples of concrete mortar.

Fill half of the contents of the samples and do mold with compaction by rodding 25 times. Compaction can also be done on a vibrating table.

Fill another sample of the concrete cylinder to mold a bit overwhelmed. Perform rodding 25 times up over the first layer

Flatten concrete overflow, spill clean-up spills and stuck to the concrete around the mold

Label. Place in a shady and dry place and let the concrete set for at least 24 hours.

Open the mold and bring to a laboratory for concrete cylinder compressive strength test.

0 comments:

Post a Comment